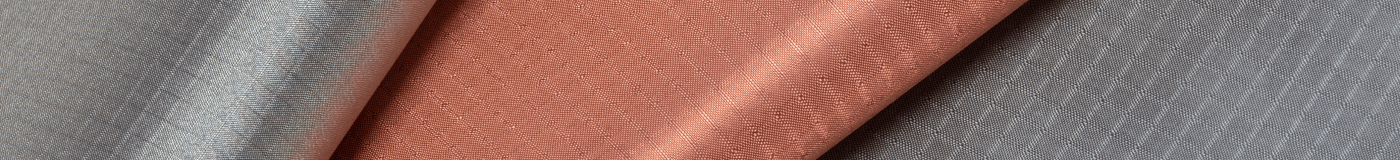

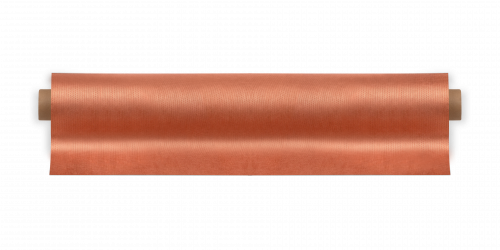

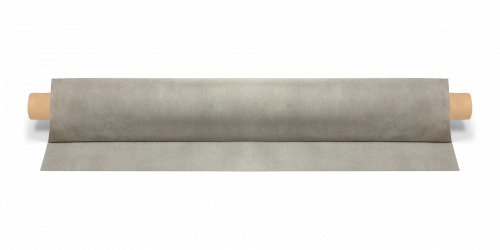

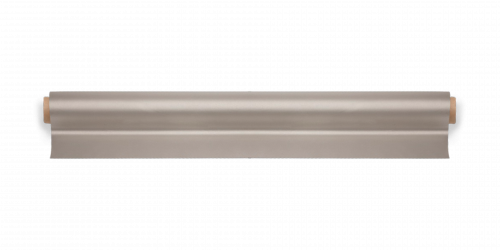

Woven

Shieldex woven fabrics act as technical textiles in the field of textile conductive paths, sensors and as shielding fabric in the shielding of electromagnetic radiation. Due to their low weight, the woven fabrics are worked into various technical products as EMC shielding fabrics – including in our shielded tents and shielding pouches.